Why Quality Matters

A few decades ago, Japan was in ruins. Post-war devastation had left its economy shattered and its industries weak. Yet, the nation made a decision—to rebuild on the foundation of quality. From automobiles to electronics, Japan rose to dominate the world stage not by being the cheapest, but by being the most trusted. “Made in Japan” soon became a global symbol of reliability, safety, and excellence.

Today, India stands at a similar turning point. With ‘Make in India’ and massive infrastructure projects reshaping the nation, we are building not just roads and skyscrapers but also our reputation in the world. Prime Minister Narendra Modi has often appealed to industries, saying:

“Zero defect, zero effect – our products must be without faults and without harm to the environment.”

This is not just a slogan—it’s a call to make quality the very DNA of Indian growth.

The Challenge We Face

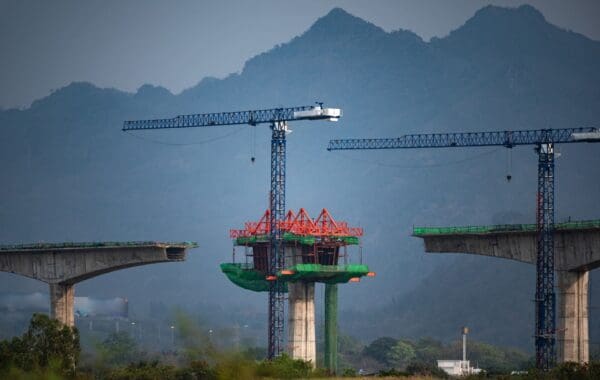

Step into a construction site in Mumbai or a factory in Gujarat, and you’ll witness the dual reality of Indian progress. On one hand, the ambition is huge—metros, highways, smart cities, exports. On the other, cracks often appear—literally and figuratively. Bridges collapse, buildings weaken, exports get rejected, and trust erodes.

Why? Because we sometimes choose shortcuts over standards, cost over quality. And in a global economy, these choices don’t just cost money—they cost credibility.

When Quality Falters – Real Lives Shatter

Here’s the sobering truth: our infrastructure’s failures aren’t distant warnings—they’re happening now.

Bridge collapse in Pune (June 2025): The Kundmala Bridge folded in on itself, claiming four lives and injuring over fifty Wikipedia.

Gujarat’s Gambhira Bridge disaster (July 2025): A 43-year-old structure broke, killing 22. Authorities ordered inspections on 1,800+ bridges immediately following WikipediaAP News.

Morbi pedestrian bridge (2022): A tragic collapse that killed 141 and injured more than 180 Wikipedia.

Across four decades (1977–2017): Over 2,130 bridges collapsed or failed during construction—average lifespan only ~35 years, significantly below the global average of 50 Taylor & Francis OnlineIndia TodayMoneycontrol.

Aging assets: India has over 163,000 public infrastructure assets, with 30% more than a century old RediffBusiness Standard.

Pune’s urgent audit: Of 777 bridges, five deemed unsafe and 136 need urgent repairs The Times of India+1.

These aren’t statistics—they’re human tragedies. Lives lost, trust shattered, progress stalled.

The Japanese Lesson

The Japanese ethic of Kaizen (continuous improvement) and uncompromising discipline offers India a roadmap. Their approach is simple yet powerful:

Do it right the first time.

Take pride in craftsmanship.

Build for generations, not just for projects.

Imagine if every cement batch, every steel rod, every brick in India was tested with this mindset. Imagine if “Made in India” carried the same trust as “Made in Japan.” That’s not just possible—it’s urgent.

The Role of Quality Guardians

This is where organizations like Global Lab Material Testing become game changers. They are not just testing cement, concrete, and steel; they are safeguarding dreams. Every bridge they test is a child’s safe school commute. Every slab they certify is a family’s secure home. Every structure they approve is a nation’s promise of progress.

Global Lab, with its NABL-accredited precision and ethical responsibility, represents the Japanese philosophy India must adopt—quality without compromise. By ensuring materials meet international standards, they help Indian companies step confidently into global markets.

A Call to Action

India doesn’t lack talent, scale, or ambition. What we need is the ethics of quality to bind it all together. If Japan could rise from the ashes to become a quality powerhouse, India—richer in resources and manpower—can surely lead the 21st century by making quality its strongest identity.

As the Prime Minister rightly urged: “Our mantra must be: zero defect, zero effect.” This is not just about manufacturing or construction. It’s about leaving behind a legacy of trust, safety, and excellence.

And as Global Lab Material Testing proves every day—when quality is prioritized, growth is inevitable, and trust is unshakable.