Procedure, Acceptance Criteria & Common Failure Causes Explained

Concrete is the core strength of every RCC structure. Whether it is a residential tower, a commercial complex, or a national infrastructure project, the performance of concrete determines the safety, durability, and service life of the structure. This is why Concrete Cube Testing as per IS 516 is treated as a mandatory quality control activity across construction sites in India.

IS 516 lays down the standard method for determining the compressive strength of concrete, ensuring that the concrete delivered at site meets the approved design requirements.

1. What is Concrete Cube Testing?

Concrete cube testing is a destructive laboratory test carried out to measure the compressive strength of hardened concrete. Fresh concrete is collected from site, cast into standard cube moulds, cured under controlled conditions, and crushed in a compression testing machine at defined ages.

The most commonly tested age is 28 days, as it represents the full strength development of concrete under normal conditions. Early-age tests at 7 days are also conducted for preliminary assessment.

2. Why Concrete Cube Testing is Critical

Concrete cube testing directly supports:

- Structural safety and load-bearing performance

- Compliance with approved mix design

- Quality assurance during RCC execution

- Consultant and client approvals

- Dispute resolution in case of failures

- In large projects, even a single failed cube can halt RCC work and lead to significant project delays and cost escalation. This makes consistent testing a commercial necessity, not just a technical requirement.

3. Standard Cube Size as per IS 516

As per Indian standards, the recommended cube size is:

150 mm × 150 mm × 150 mm

This size is universally adopted for site quality control and acceptance testing. Smaller 100 mm cubes may be used only in controlled laboratory applications.

4. Step-by-Step Procedure of Concrete Cube Testing (IS 516)

4.1 Sampling of Fresh Concrete

Concrete is sampled directly from the mixer, transit mixer, or pump discharge point to ensure a true representation of site concrete.

4.2 Preparation of Cube Moulds

Moulds are cleaned thoroughly and lightly oiled on the inner surfaces. This ensures proper shape and smooth demoulding.

4.3 Filling and Compaction

Concrete is placed in the mould in three equal layers. Each layer is compacted either by:

Tamping with standard tamping rod (35 strokes per layer), or

Mechanical vibration using a table vibrator.

Proper compaction is essential to eliminate air voids that reduce strength.

4.4 Finishing

The top surface of the cube is finished level and smooth using a trowel.

4.5 Initial Setting and Demoulding

Cubes are stored at a temperature of 27 ± 2°C for 24 hours and then carefully demoulded.

4.6 Water Curing

Demoulded cubes are placed in a curing tank containing clean, potable water until the day of testing (7, 14, or 28 days).

4.7 Compression Testing

At the specified age, cubes are tested in a calibrated Compression Testing Machine (CTM). Load is applied uniformly until failure, and the peak load is recorded.

5. Calculation of Compressive Strength

Compressive Strength = Maximum Load at Failure (N)

Cross-sectional Area of Cube (mm²)

For a 150 mm cube:

Area = 22,500 mm²

6. Acceptance Criteria as per IS 456

For acceptance of concrete:

The average strength of three cubes must be equal to or greater than the characteristic strength (fck).

No individual cube should be less than:

fck–3 N/mm²

This ensures both overall consistency and individual reliability of concrete batches.

7. Common Causes of Concrete Cube Failure

Most cube failures originate at the site execution stage rather than in the laboratory. The most frequent causes include:

• Excess Water in Concrete

High water–cement ratio reduces strength drastically.

• Poor Compaction

Inadequate vibration leads to internal voids and weak zones.

• Inadequate Curing

Improper curing affects hydration and long-term strength gain.

• Deviation from Approved Mix Design

Unauthorized changes in proportion directly affect performance.

• Improper Cube Casting

Untrained handling, damaged moulds, and incorrect sampling result in unreliable test outcomes.

8. Importance of NABL-Accredited Testing

Concrete cube testing must be conducted only in a NABL-accredited laboratory to ensure:

- Calibrated testing equipment

- Technically validated procedures

- Traceable and legally acceptable results

- Acceptance in government audits and third-party inspections

Reports issued by non-accredited laboratories are often rejected in statutory approvals and legal disputes.

9. Where Concrete Cube Testing is Mandatory

Cube testing is mandatory for:

- Foundations and footings

- Columns, beams, and slabs

- Raft and pile foundations

- High-rise RCC buildings

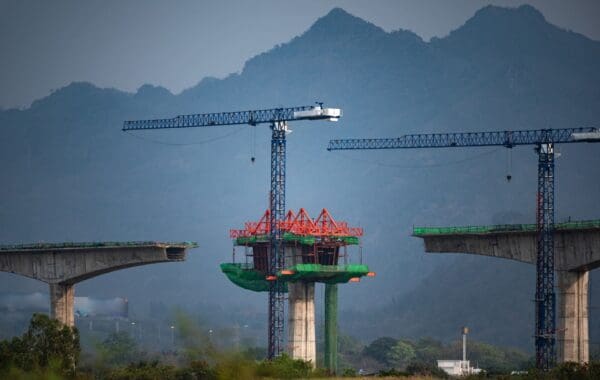

- Bridges, flyovers, and metro structures

- Industrial floors and retaining walls

10. Closing Perspective

Concrete cube testing under IS 516 is not merely a compliance formality—it is a direct assurance of structural safety and long-term performance. Every cube tested represents a real portion of the structure that will eventually carry human lives, heavy loads, and continuous service demands.

For project owners, consultants, and contractors, systematic cube testing ensures:

- Reduced structural risk

- Higher construction confidence

- Better lifecycle performance

- Protection from future liabilities

In a time where speed and scale dominate construction, quality remains the only true guarantee of sustainability.