Global Lab Advantage.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Modern tall buildings demand materials with high load-bearing capacity and minimal section sizes. HPC, with compressive strengths often exceeding 55–100 MPa, enables slender, lightweight structural members that reduce dead load and free up usable floor space. Its superior modulus of elasticity and reduced creep make it ideal for towers, mega-columns, and transfer girders in high-rise construction.

HPC is designed for superior resistance to harsh exposure environments: Tall building, Coastal & Marine Structures: Bridges, piers, and seawalls face continuous chloride exposure from saltwater. HPC’s dense pore structure limits chloride penetration, preventing reinforcement corrosion and extending service life. Industrial & Chemical Plants: HPC resists acid and sulfate attack in plants, factories, and refineries through low permeability and chemical resistance. Cold Climate Structures: Air-entrained HPC prevents freeze–thaw cracking by minimizing water absorption and providing controlled air voids.

In bridges, dams, tunnels, and nuclear containment structures, strength alone is not enough — performance under pressure, temperature, and stress is critical. HPC offers high tensile strength, ductility, and reduced creep and shrinkage, enabling the design of long-span bridges, prestressed elements, and containment structures that maintain structural integrity under extreme loads.

While the initial material cost of HPC may be higher, it provides substantial long-term economic benefits: Reduced Maintenance: Longer service intervals and reduced repair frequency. Accelerated Construction: High early-age strength enables faster formwork removal and construction turnaround. Optimized Structural Design: Higher strength-to-weight ratio allows smaller sections, reduced concrete volume, and lighter foundations — lowering overall project cost. HPC delivers both performance excellence and lifecycle economy, making it the preferred choice for value-driven construction.

NDT TESTING

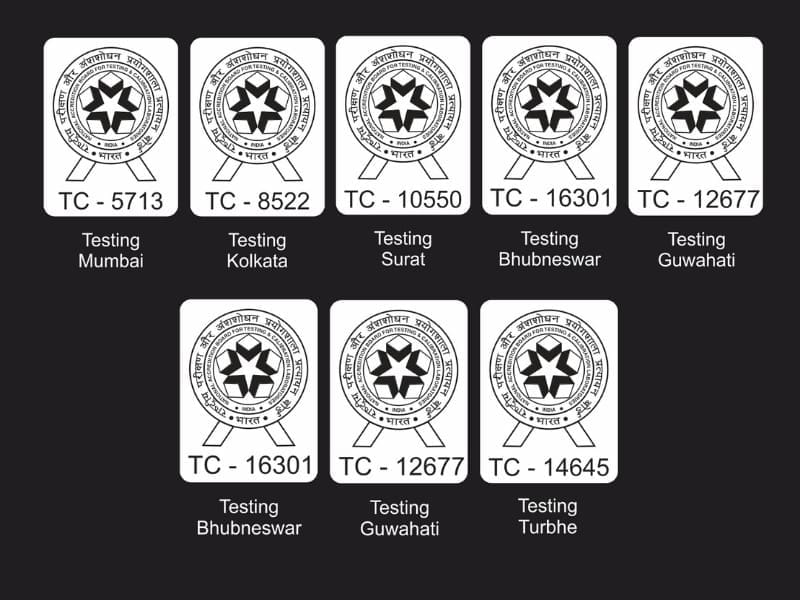

Accredited Facility: NABL-accredited laboratory with traceable calibration and stringent Quality System procedures.

Compliance with Standards: Tests conducted in accordance with relevant IS/ASTM/RILEM/EN standards.

Experienced Personnel: Technologists and experts who interpret results and recommend mitigation strategies.

Rapid and Reliable Reporting: Valid reports that comply with relevant standards.

Testing Capabilities: Lab and on-site testing, along with post-test consulting services.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

NABL Accredited

Advanced Lab & Field Testing

Fast Turnaround Reports

Digital Data & Traceability

On-Site Testing Across India

Global Lab provides comprehensive testing for construction and engineering materials, including concrete, cement, steel, aggregates, bitumen, soil, tiles, paver blocks, and other civil and infrastructure materials. We also handle customized tests as per client or project specifications.

Material testing ensures that every component used in a structure meets the required strength, durability, and safety standards. It helps prevent structural failures, ensures long-term performance, and guarantees compliance with national and international standards.

Yes. Global Lab is an NABL-accredited and ISO-certified facility. All our tests are carried out in accordance with the latest IS, ASTM, BS, and EN standards to maintain accuracy, reliability, and traceability of results.

Yes. Our team is equipped with mobile testing facilities and field instruments for on-site sampling, inspection, and testing — ensuring quick and reliable results without disrupting your project timelines.

We follow a wide range of standards including IS (Bureau of Indian Standards), ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Norms) — depending on project or client requirements.

Yes. We provide digital test reports with QR-code verification, ensuring easy access, authenticity, and transparency for clients, consultants, and contractors.

With years of experience, NABL accreditation, and thousands of successful test reports delivered, Global Lab has built a reputation for accuracy, transparency, and technical integrity. Our results are accepted by top builders, government bodies, and consultants across India.

Global Lab serves a broad range of industries — including construction, infrastructure, real estate, government projects, precast manufacturers, RMC plants, and consultants — offering reliable testing, calibration, inspection, and proficiency services.

Adding {{itemName}} to cart

Added {{itemName}} to cart