Global Lab Advantage.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Innovative Solution for Testing Large, Deep, and High-Capacity Piles

The BDSLT can safely apply massive test loads that would otherwise require an enormous and expensive top-down reaction setup. By using the pile and surrounding soil as the reaction system, the embedded hydraulic jack applies an upward load (mobilizing skin friction above) and a downward load (mobilizing skin friction and end bearing below). This allows testing of high-capacity piles that exceed the limitations of conventional load tests.

A key advantage of this method is the ability to independently measure the skin friction and end-bearing resistance within a single test. When the internal jack is activated, it records upward and downward movements separately—giving engineers precise insight into how the pile transfers loads through different soil layers. This data helps optimise pile design, reducing material use while ensuring safety and reliability.

Unlike traditional static load tests that require heavy kentledge setups or anchor piles, the BDSLT eliminates external reaction systems entirely. It saves significant setup time, equipment costs, and space, making it ideal for sites with logistical challenges or tight project schedules. Testing can be completed faster and with far fewer resources, without compromising accuracy.

In cases where piles extend deep into stiff strata or rock, conventional top-down tests often fail to mobilise full resistance. By positioning the hydraulic jack assembly within the pile at depth, the BDSLT can directly activate and measure resistance in lower soil or rock layers. This ensures accurate assessment of total pile capacity—especially in bridges, offshore structures, and high-rise foundations.

NDT TESTING

Accredited Facility: NABL-accredited laboratory with traceable calibration and stringent Quality System procedures.

Compliance with Standards: Tests conducted in accordance with relevant IS/ASTM/RILEM/EN standards.

Experienced Personnel: Technologists and experts who interpret results and recommend mitigation strategies.

Rapid and Reliable Reporting: Valid reports that comply with relevant standards.

Testing Capabilities: Lab and on-site testing, along with post-test consulting services.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

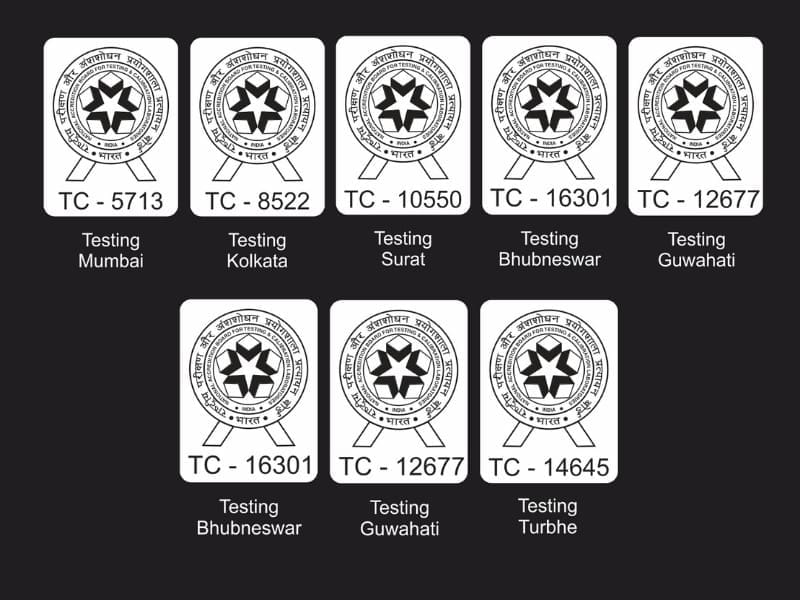

NABL Accredited

Advanced Lab & Field Testing

Fast Turnaround Reports

Digital Data & Traceability

On-Site Testing Across India

Global Lab provides comprehensive testing for construction and engineering materials, including concrete, cement, steel, aggregates, bitumen, soil, tiles, paver blocks, and other civil and infrastructure materials. We also handle customized tests as per client or project specifications.

Material testing ensures that every component used in a structure meets the required strength, durability, and safety standards. It helps prevent structural failures, ensures long-term performance, and guarantees compliance with national and international standards.

Yes. Global Lab is an NABL-accredited and ISO-certified facility. All our tests are carried out in accordance with the latest IS, ASTM, BS, and EN standards to maintain accuracy, reliability, and traceability of results.

Yes. Our team is equipped with mobile testing facilities and field instruments for on-site sampling, inspection, and testing — ensuring quick and reliable results without disrupting your project timelines.

We follow a wide range of standards including IS (Bureau of Indian Standards), ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Norms) — depending on project or client requirements.

Yes. We provide digital test reports with QR-code verification, ensuring easy access, authenticity, and transparency for clients, consultants, and contractors.

With years of experience, NABL accreditation, and thousands of successful test reports delivered, Global Lab has built a reputation for accuracy, transparency, and technical integrity. Our results are accepted by top builders, government bodies, and consultants across India.

Global Lab serves a broad range of industries — including construction, infrastructure, real estate, government projects, precast manufacturers, RMC plants, and consultants — offering reliable testing, calibration, inspection, and proficiency services.

Adding {{itemName}} to cart

Added {{itemName}} to cart