Global Lab Advantage.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

The primary purpose of the test is to determine the axial load-carrying capacity of a pile. By applying a controlled dynamic impact, the test replicates the loading conditions of a structure, allowing engineers to accurately calculate both shaft friction and end bearing capacity.

Unlike static load tests that can take several days and require elaborate reaction systems, PDLT can be performed in a few hours with minimal setup. This makes it ideal for projects with a large number of piles, such as bridges, metro lines, ports, or high-rise buildings — where time and cost savings are crucial.

The waveform analysis from the sensors provides valuable insight into the structural condition of the pile. Defects like cracks, necking, bulging, or discontinuities can be identified by changes in wave velocity or reflection patterns, helping to ensure pile soundness before load application.

For driven piles, dynamic testing can be conducted during or immediately after installation. The results provide real-time feedback on hammer energy, driving resistance, and pile stresses — allowing engineers to optimise driving criteria to achieve the required bearing capacity without overstressing or damaging the pile.

NDT TESTING

Accredited Facility: NABL-accredited laboratory with traceable calibration and stringent Quality System procedures.

Compliance with Standards: Tests conducted in accordance with relevant IS/ASTM/RILEM/EN standards.

Experienced Personnel: Technologists and experts who interpret results and recommend mitigation strategies.

Rapid and Reliable Reporting: Valid reports that comply with relevant standards.

Testing Capabilities: Lab and on-site testing, along with post-test consulting services.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

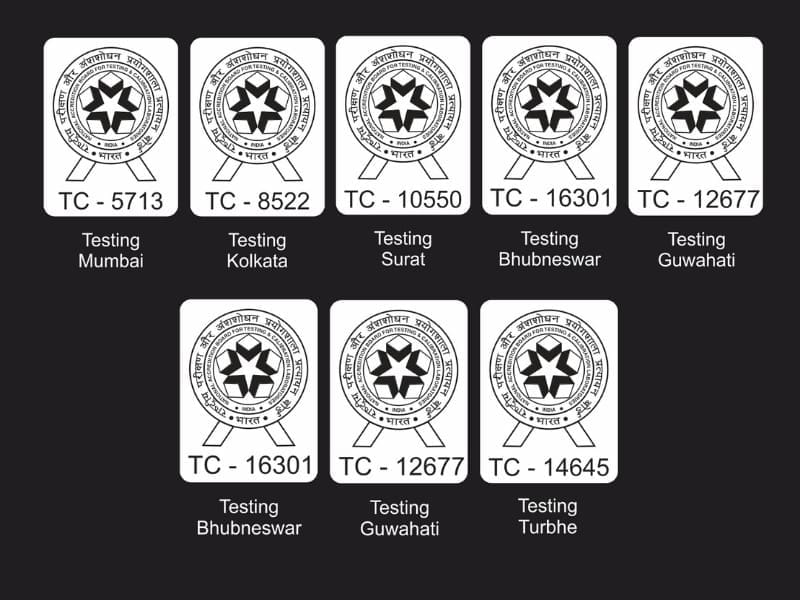

NABL Accredited

Advanced Lab & Field Testing

Fast Turnaround Reports

Digital Data & Traceability

On-Site Testing Across India

Global Lab provides comprehensive testing for construction and engineering materials, including concrete, cement, steel, aggregates, bitumen, soil, tiles, paver blocks, and other civil and infrastructure materials. We also handle customized tests as per client or project specifications.

Material testing ensures that every component used in a structure meets the required strength, durability, and safety standards. It helps prevent structural failures, ensures long-term performance, and guarantees compliance with national and international standards.

Yes. Global Lab is an NABL-accredited and ISO-certified facility. All our tests are carried out in accordance with the latest IS, ASTM, BS, and EN standards to maintain accuracy, reliability, and traceability of results.

Yes. Our team is equipped with mobile testing facilities and field instruments for on-site sampling, inspection, and testing — ensuring quick and reliable results without disrupting your project timelines.

We follow a wide range of standards including IS (Bureau of Indian Standards), ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Norms) — depending on project or client requirements.

Yes. We provide digital test reports with QR-code verification, ensuring easy access, authenticity, and transparency for clients, consultants, and contractors.

With years of experience, NABL accreditation, and thousands of successful test reports delivered, Global Lab has built a reputation for accuracy, transparency, and technical integrity. Our results are accepted by top builders, government bodies, and consultants across India.

Global Lab serves a broad range of industries — including construction, infrastructure, real estate, government projects, precast manufacturers, RMC plants, and consultants — offering reliable testing, calibration, inspection, and proficiency services.

Adding {{itemName}} to cart

Added {{itemName}} to cart