Global Lab Advantage.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Evaluation of coating thickness, adhesion, integrity, and protective performance of polyethylene coatings on metal pipelines and steel structures

Polyethylene coating acts as a barrier against: Soil corrosivity, Chemical attack, Moisture penetration, UV & environmental degradation. Testing verifies that the coating is applied correctly and provides maximum corrosion resistance.

Typical defects include: Pinhole/holidays, Porosity, Thin coating areas, Disbonded coating, Mechanical damage during transport or installation Testing prevents major failures such as leakage, rusting, and premature pipeline deterioration.

PE coatings must meet the specifications provided in: IS 10289 – External Fusion Bonded Epoxy/PE Coatings for Steel Pipes, IS 3589 / IS 4984 – Pipe Specifications, ISO 21809-1 – Coatings for Pipeline Transportation Systems, DIN 30670 – Polyethylene Coatings for Steel Pipes, Project or client QA/QC requirements, Testing ensures coating is consistent, durable, and approved for service.

Proper coating ensures: Extended service life of metal pipelines, Reduced corrosion and maintenance frequency, Lower risk of costly shutdowns, Improved reliability of underground and submerged systems A well-tested coating system leads to safer and more economical infrastructure operations.

NDT TESTING

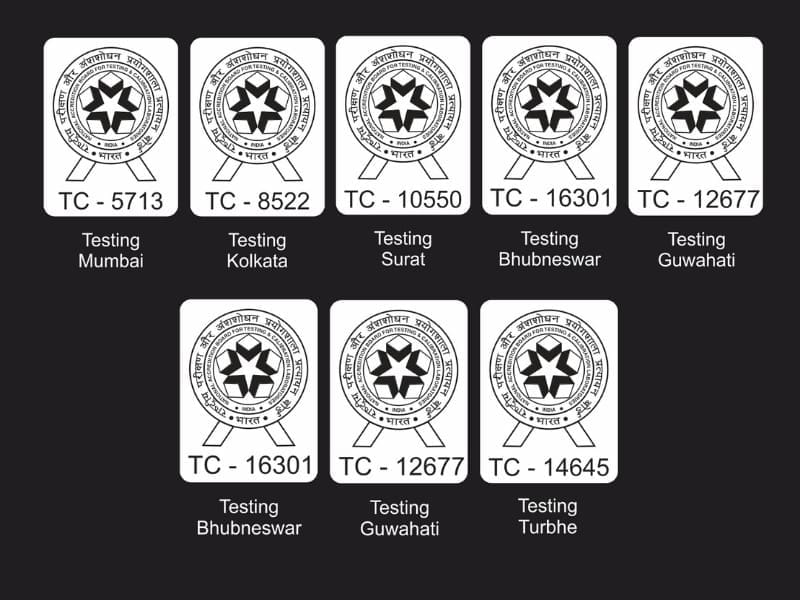

Accredited Facility: NABL-accredited laboratory with traceable calibration and stringent Quality System procedures.

Compliance with Standards: Tests conducted in accordance with relevant IS/ASTM/RILEM/EN standards.

Experienced Personnel: Technologists and experts who interpret results and recommend mitigation strategies.

Rapid and Reliable Reporting: Valid reports that comply with relevant standards.

Testing Capabilities: Lab and on-site testing, along with post-test consulting services.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Applications

Polyethylene Coating Test on Metal is essential for: Oil & gas pipelines, Water transmission pipelines, Underground & submerged steel pipelines, Storage tanks & steel reservoir, Industrial plant pipelines, Structural steel in corrosive environments, Marine, offshore & harbor installations

Any metal component requiring corrosion protection validation

NABL Accredited

Advanced Lab & Field Testing

Fast Turnaround Reports

Digital Data & Traceability

On-Site Testing Across India

Global Lab provides comprehensive testing for construction and engineering materials, including concrete, cement, steel, aggregates, bitumen, soil, tiles, paver blocks, and other civil and infrastructure materials. We also handle customized tests as per client or project specifications.

Material testing ensures that every component used in a structure meets the required strength, durability, and safety standards. It helps prevent structural failures, ensures long-term performance, and guarantees compliance with national and international standards.

Yes. Global Lab is an NABL-accredited and ISO-certified facility. All our tests are carried out in accordance with the latest IS, ASTM, BS, and EN standards to maintain accuracy, reliability, and traceability of results.

Yes. Our team is equipped with mobile testing facilities and field instruments for on-site sampling, inspection, and testing — ensuring quick and reliable results without disrupting your project timelines.

We follow a wide range of standards including IS (Bureau of Indian Standards), ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Norms) — depending on project or client requirements.

Yes. We provide digital test reports with QR-code verification, ensuring easy access, authenticity, and transparency for clients, consultants, and contractors.

With years of experience, NABL accreditation, and thousands of successful test reports delivered, Global Lab has built a reputation for accuracy, transparency, and technical integrity. Our results are accepted by top builders, government bodies, and consultants across India.

Global Lab serves a broad range of industries — including construction, infrastructure, real estate, government projects, precast manufacturers, RMC plants, and consultants — offering reliable testing, calibration, inspection, and proficiency services.

Adding {{itemName}} to cart

Added {{itemName}} to cart