Global Lab Advantage.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Strain monitoring helps engineers observe how a structure actually performs when subjected to: Live loads, Dead loads, Environmental effects, Temperature changes, and Operational vibrations. This real-time data ensures the structure is behaving within safe design limits.

Continuous or periodic strain measurement identifies: Overloaded or overstressed areas, Fatigue cracking tendencies, Localised material degradation, Weak points in critical load paths. This allows corrective action before a structural issue becomes dangerous.

Strain monitoring verifies whether: Designed load capacities are achieved, Actual behaviour matches theoretical modelling, Strengthening or retrofitting is required, IS, IRC, and international code requirements are met.

By understanding strain trends over time, engineers can: Predict potential failures, Plan timely maintenance, Avoid sudden breakdowns, Reduce repair costs, Improve asset lifetime This enhances safety, reliability, and long-term performance of the structure.

NDT TESTING

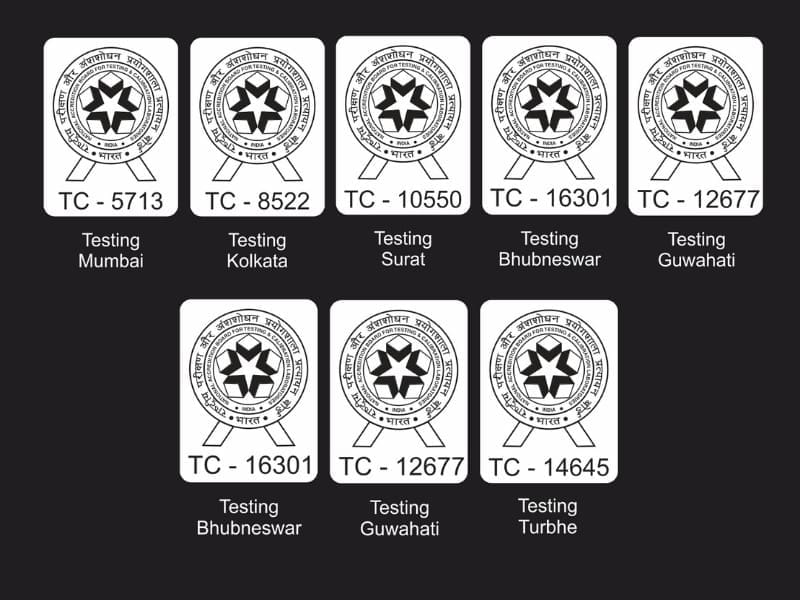

Accredited Facility: NABL-accredited laboratory with traceable calibration and stringent Quality System procedures.

Compliance with Standards: Tests conducted in accordance with relevant IS/ASTM/RILEM/EN standards.

Experienced Personnel: Technologists and experts who interpret results and recommend mitigation strategies.

Rapid and Reliable Reporting: Valid reports that comply with relevant standards.

Testing Capabilities: Lab and on-site testing, along with post-test consulting services.

Accredited facility.

Standards compliance.

Experienced analysts.

Fast, reliable reporting.

Field + Lab capability.

Applications

Structural Strain Monitoring is essential for: Bridges & flyovers, High-rise buildings, Industrial structures & plants, Precast & post-tensioned structures, Tanks, silos & storage structures, Metro rails & elevated corridors, Foundations & retaining structures

Structures undergoing rehabilitation or proof load testing

NABL Accredited

Advanced Lab & Field Testing

Fast Turnaround Reports

Digital Data & Traceability

On-Site Testing Across India

Global Lab provides comprehensive testing for construction and engineering materials, including concrete, cement, steel, aggregates, bitumen, soil, tiles, paver blocks, and other civil and infrastructure materials. We also handle customized tests as per client or project specifications.

Material testing ensures that every component used in a structure meets the required strength, durability, and safety standards. It helps prevent structural failures, ensures long-term performance, and guarantees compliance with national and international standards.

Yes. Global Lab is an NABL-accredited and ISO-certified facility. All our tests are carried out in accordance with the latest IS, ASTM, BS, and EN standards to maintain accuracy, reliability, and traceability of results.

Yes. Our team is equipped with mobile testing facilities and field instruments for on-site sampling, inspection, and testing — ensuring quick and reliable results without disrupting your project timelines.

We follow a wide range of standards including IS (Bureau of Indian Standards), ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Norms) — depending on project or client requirements.

Yes. We provide digital test reports with QR-code verification, ensuring easy access, authenticity, and transparency for clients, consultants, and contractors.

With years of experience, NABL accreditation, and thousands of successful test reports delivered, Global Lab has built a reputation for accuracy, transparency, and technical integrity. Our results are accepted by top builders, government bodies, and consultants across India.

Global Lab serves a broad range of industries — including construction, infrastructure, real estate, government projects, precast manufacturers, RMC plants, and consultants — offering reliable testing, calibration, inspection, and proficiency services.

Adding {{itemName}} to cart

Added {{itemName}} to cart